Transforming the Way you Build, Design, and Innovate with AR/VR

OVERVIEW

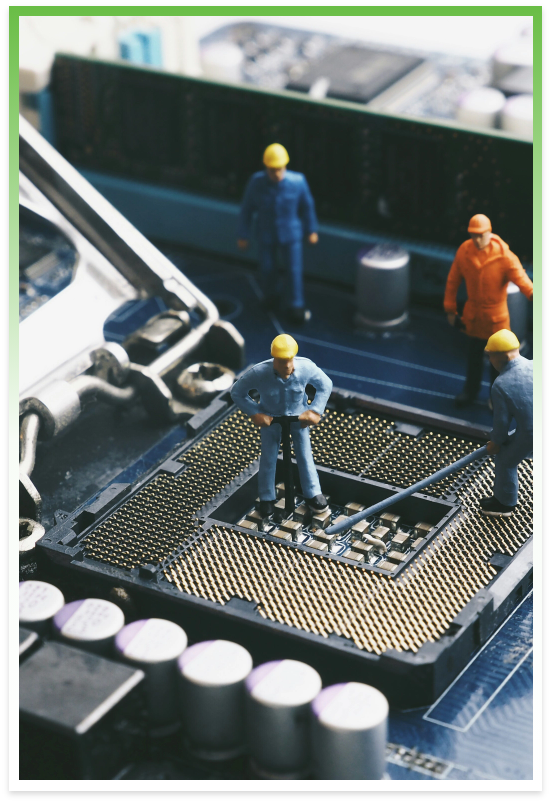

Immersive technologies are transforming the manufacturing industry by providing new and innovative ways to design, simulate, and visualise products and processes. Allow users to interact with the physical world in a more immersive and intuitive way, enabling them to perform complex tasks with greater ease and accuracy. VR/AR now make it possible for engineers to visualise the production process to gain visual acuity and make accurate predictions of potential conflicts long before they occur.

FEATURES OF AR/VR IN MANUFACTURING

DESIGN VISUALISATION

AR/VR technologies can be used to visualise 3D models of products and components before they are manufactured, allowing engineers to detect and correct any design flaws early in the design process. This can reduce costs and improve product quality.

ASSEMBLY AND MAINTENANCE

With AR/VR technologies, users can provide step-by-step instructions to employees during the assembly and maintenance providing workers with a realistic training experience without the need for physical equipment. This can reduce errors and improve efficiency.

ASSEMBLY AND MAINTENANCE

With AR/VR technologies, users can provide step-by-step instructions to employees during the assembly and maintenance providing workers with a realistic training experience without the need for physical equipment. This can reduce errors and improve efficiency.

QUALITY CONTROL

AR/VR can be used to enhance quality control and inspection processes by allowing inspectors to overlay digital information onto physical objects in real-time. This can help to identify defects, improve accuracy, and reduce the risk of errors.

REMOTE COLLABORATION

VR and AR can be used to facilitate remote collaboration between engineers and manufacturing teams. For example, engineers can use VR to remotely inspect a factory floor or collaborate with manufacturing teams in different locations.

REMOTE COLLABORATION

VR and AR can be used to facilitate remote collaboration between engineers and manufacturing teams. For example, engineers can use VR to remotely inspect a factory floor or collaborate with manufacturing teams in different locations.

MARKETING AND SALES

VR technology can be used to create immersive product demonstrations for potential customers, allowing them to interact with the product before purchasing. This can increase sales and reduce product returns.

KEY BENEFITS OF AR/VR IN MANUFACTURING

Simulation

AR/VR can simulate real-world scenarios and help manufacturers test different solutions before implementing them in real life.

Training

AR/VR technology can be used for employee training, providing a safe and cost-effective way to train workers on new equipment or processes.

Inventory Management

AR/VR can be used to manage inventory, allowing workers to quickly locate and track products in real-time.

Visualisation

AR/VR can provide manufacturers with a more immersive and interactive way to visualise their designs, products, and manufacturing processes.

Product Design

AR/VR can be used in the product design process to allow designers to visualize and test different product features and configurations.

OUR SOLUTIONS

3D SOLUTIONS

We offer high accuracy 3D modeling solutions for all industrial requirements.

APP SOLUTIONS

We help manufacturing companies with mobile applications in monitoring production and Management.

XR SOLUTIONS

We help you reduce cost, improve training and operations to stay competitive.

WEB SOLUTIONS

We deliver unique and secure web development solutions that matches your business strategies and requirements.

Revolutionize your manufacturing processes with AR/VR solutions

Let us know how we can assist your industry in embracing the limitless possibilities of the AR, VR and Metaverse. Fill out the form below, and our team will get in touch with you promptly.

Virtual reality engineering includes 3D modelling tools and visualisation techniques as part of the design process. They help the design team to observe their project within a safe and virtual environment.

VR technologies are used by design engineers to identify errors with a product and rectify them before a physical prototype is done.

Virtual reality in manufacturing can be used as a safety barrier. The use of virtual reality allows employees to simulate the processes involved in production, which allows them to identify situations that may be dangerous.

AR headset can provide visual overlap of drawings, complex instructions, event recording or enable visual interaction.It improve employee productivity by eliminating time-wasting behaviour or improving job efficiency

In production, AR technology can be used to measure various changes, identify unsafe working conditions, or even detect a finished product.

Yes, you most certainly can but you’ll need vr development kits to navigate in virtual spaces.